capabilities

Whether you are fully tooled and ready to launch production or are beginning with an initial concept, RAGE can help you produce your product or component with superior performance and quality and bring it to market at a competitive price.

PRODUCT/PROCESS DESIGN DEVELOPMENT & ENGINEERING

RAGE’s roots are in product development and prototyping. We have decades of experience in successful product design, engineering and prototyping; mold design, development and flow simulation; process studies and product launch.

Whatever your product requirements, our team will work with you to meet them. Our customers’ applications vary from highly cosmetic, textured Class A surfaces, to very demanding tight-tolerances for large and small precision products found in business electronics, consumer appliances, and medical components to transportation equipment.

FACILITIES AND EQUIPMENT

Injection Molding

We know what it takes to meet your product’s performance requirements. In our 40+ years of supporting the needs of a wide range of industries, RAGE’s engineering and production staff has worked with all conventional engineering grade materials, as well as an extensive range of specialty resins.

We also routinely invest in new equipment and technology. We work closely with our clients to develop the best approach and systems to produce your product or component. With dozens of presses ranging from 25 tons of clamping force with a 1 oz shot capacity to 1500 tons of clamping force capacity with a 540 oz injection capacity, RAGE is positioned to support your injection molding requirements.

Injection Stretch Blow-Molding

RAGE is a strategic partner with AOKI Technical Laboratory and AOKI considers RAGE Corporation North America’s foremost authority on polypropylene injection stretch blow molding. RAGE has extensive experience operating AOKI injection blow-molding equipment and routinely collaborates with AOKI on technology development and customer product applications.

Automation and Robotics

RAGE’s molding operations are supported by an extensive selection of robotics and automation for material handling, manufacturing, assembly and packaging. Supported by in-line inspection and testing, these manufacturing cells reduce process variability and improve quality and throughput.

Secondary Operations

A full-service plastics manufacturing operation, RAGE can offer you everything required to bring your product to market, including machining, trimming, deflashing, drilling, welding, marking and labeling. RAGE also teams with customers and supply chain partners to assemble, package, sterilize, warehouse, and fulfill orders to reduce costs, improve response, and mitigate waste.

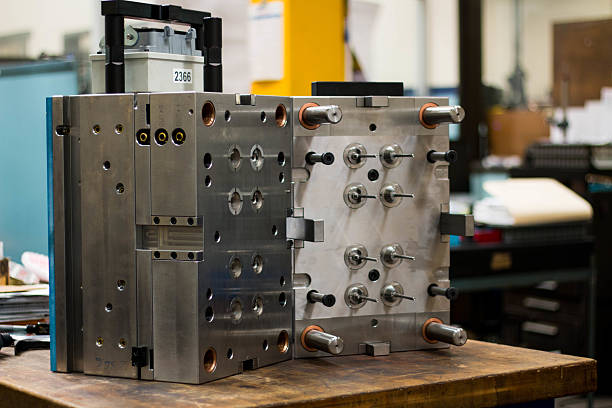

Tooling

RAGE maintains its own in-house tooling capability, and also collaborates with leading domestic and foreign tool-builders. These multiple options provide RAGE customers with flexibility in cost and delivery as they move through the product development cycle and into production.

RAGE also provides in-house tool management, including preventative maintenance, repair, modification and storage. This assures RAGE is always positioned to manufacture products and components meeting your performance and quality requirements and deliver them on time in-line with your schedule.

Quality, Analysis and Testing

RAGE combines the professionalism developed through decades of experience in both high-volume production and specialty manufacturing, with the focus and personal commitment of a family-owned company. As a result, RAGE Plastics has a 40-year history of exceeding its customers’ expectations for quality, performance and innovation in injection-molded and injection stretch blow-molded plastic products.

RAGE designs and produces components in compliance to a wide range of domestic and foreign commercial standards as well as FDA (CFR C21 Part 820) and other government specifications and military standards.

When necessary to meet unique product quality requirements, we also work with our customers’ product development teams and quality personnel to establish customized testing, documentation and reporting protocols as necessary.

RAGE’s Quality Assurance team maintains in-house laboratory capability to support routine test and evaluation requirements and has an established network of analytical laboratories and professional engineering firms to provide specialized expertise seamlessly and cost-effectively.