engineering services

Rage can work with you to take your plastic product idea from a vague concept to reality. With our expertise and sophisticated systems, we can design and produce almost any part imaginable. Rage uses IQMS and ER system that helps us control our inventory and resource planning that maximizes productivity. Automated scheduling that creates operational efficiency along with Real-time production and processing monitoring that improves our ability to exceed the customers expectations.

A Rage Project Manager will work closely with you and your team to assist in all aspects of product development, including:

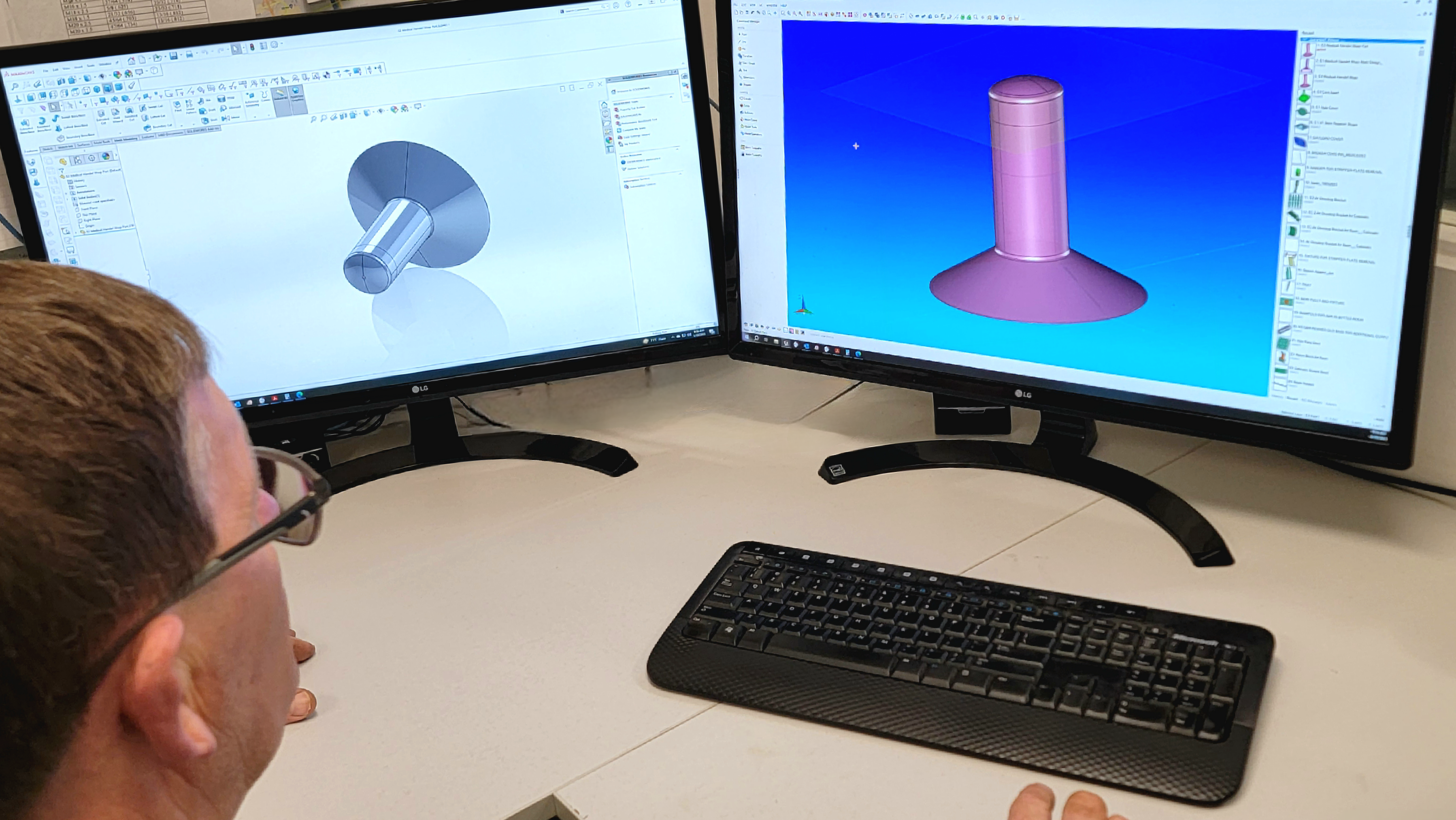

PRODUCT DESIGN

-

- Use of the latest technology to develop and deliver the optimum solution for product performance, cost, and quality

- When designing products, we work to reduce cost throughout the entire development, manufacturing and assembly processes

- We can provide innovative, creative ideas to help differentiate your product

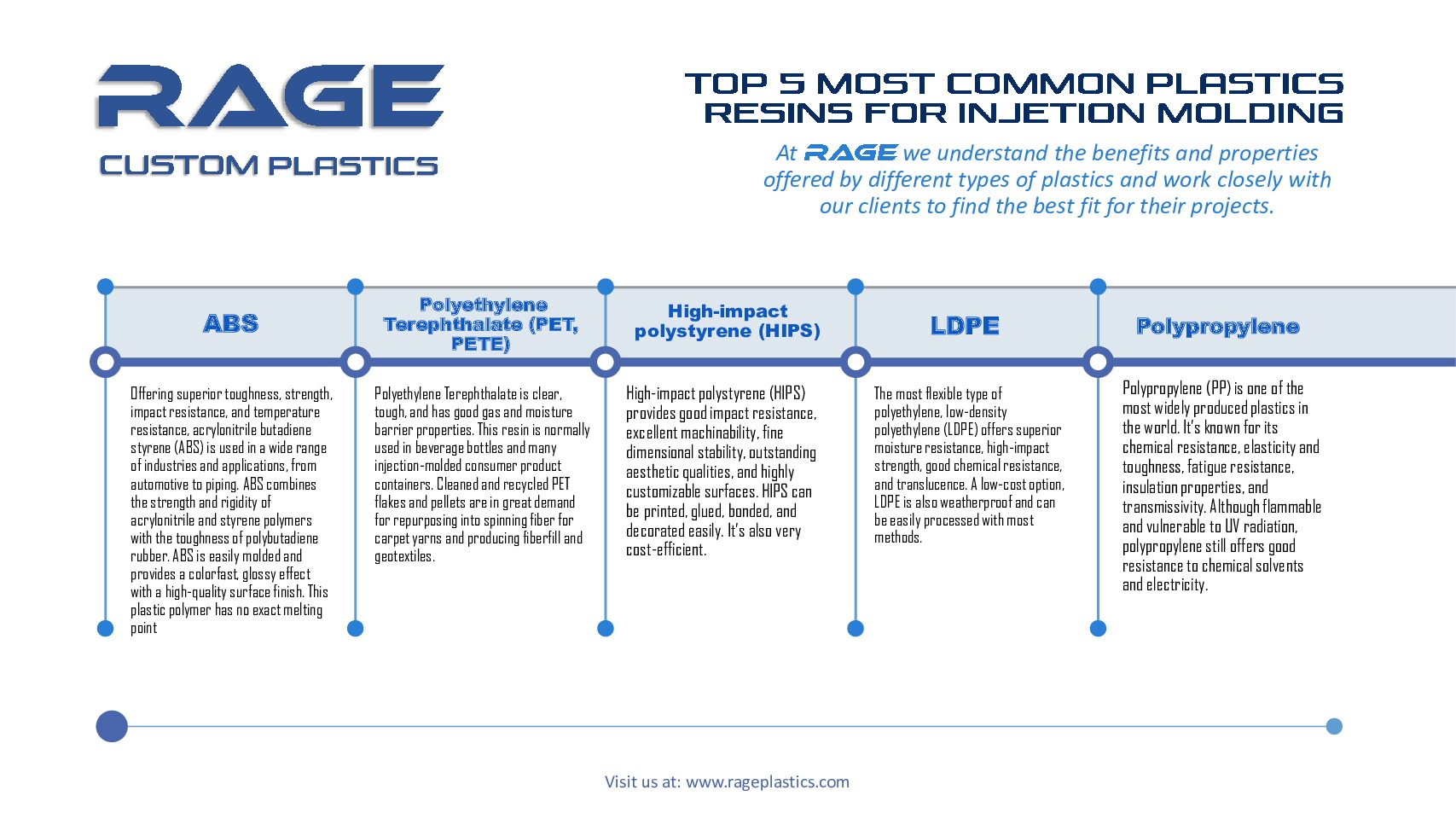

SELECTING APPROPRIATE MATERIALS

-

- Expertise in a wide range of polymer materials for a variety of industries from consumer, industrial, defense, health and beauty, bottles and packaging.

- Our staff has worked with all conventional grade materials as well as an extensive range of specialty resins

- The ability to stock over 1.5 million pounds of material gives us the additional buying leverage that allows us to keep the material cost down.

- When determining the best material for your product, we consider finished product quality and functionality, costs, logistics, environmental issues (recyclability, waste, etc.), etc.

DEVELOPING PROTOTYPES

- We have a wide range of systems to develop product prototypes to ensure the product design meets all your requirements.

- Use of prototypes to evaluate the product’s performance, proof of concept, marketing appeal, fit, functionality, compatibility with other products, etc.

DEFINING SPECIFICATIONS

- We know what it takes to meet your product’s performance requirements

- Our customers’ applications vary from highly cosmetic to very demanding tight-tolerances for large and small precision products in electronics, medical components, bottles and caps, etc.

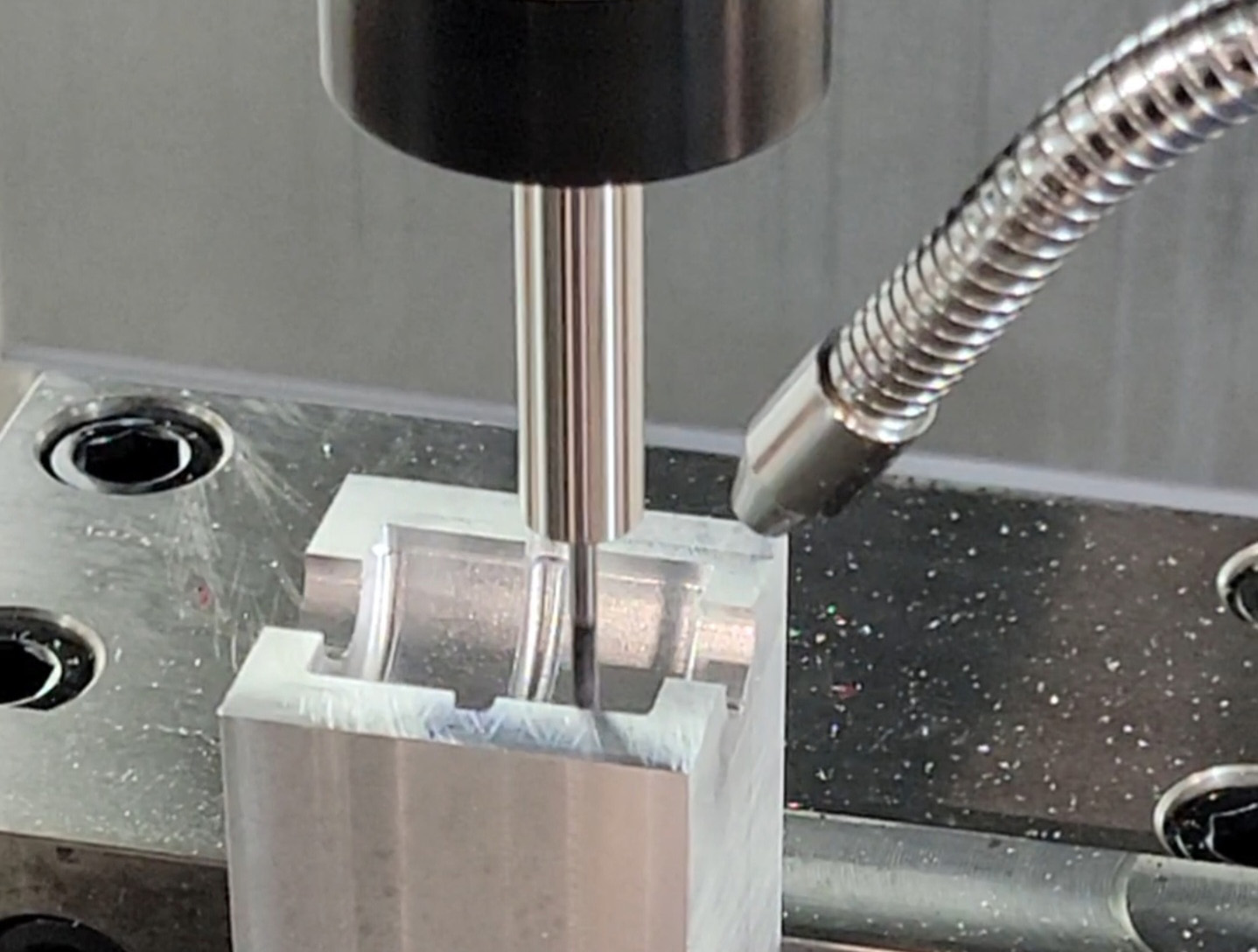

DESIGNING AND BUILDING THE MOLD

- Designing and building a mold is a major expense so ensuring the proper design and construction is critical

- Rage will work with you on complete implementation of the mold, whether we design and build the mold, you build your own mold, outsource the mold building, need expertise to solve a mold problem or optimize the molding process

- A properly designed and built mold will deliver part-to-part repeatability and reliability for many years

- We will develop an appropriate Preventive Maintenance program to maximize the life of the mold.

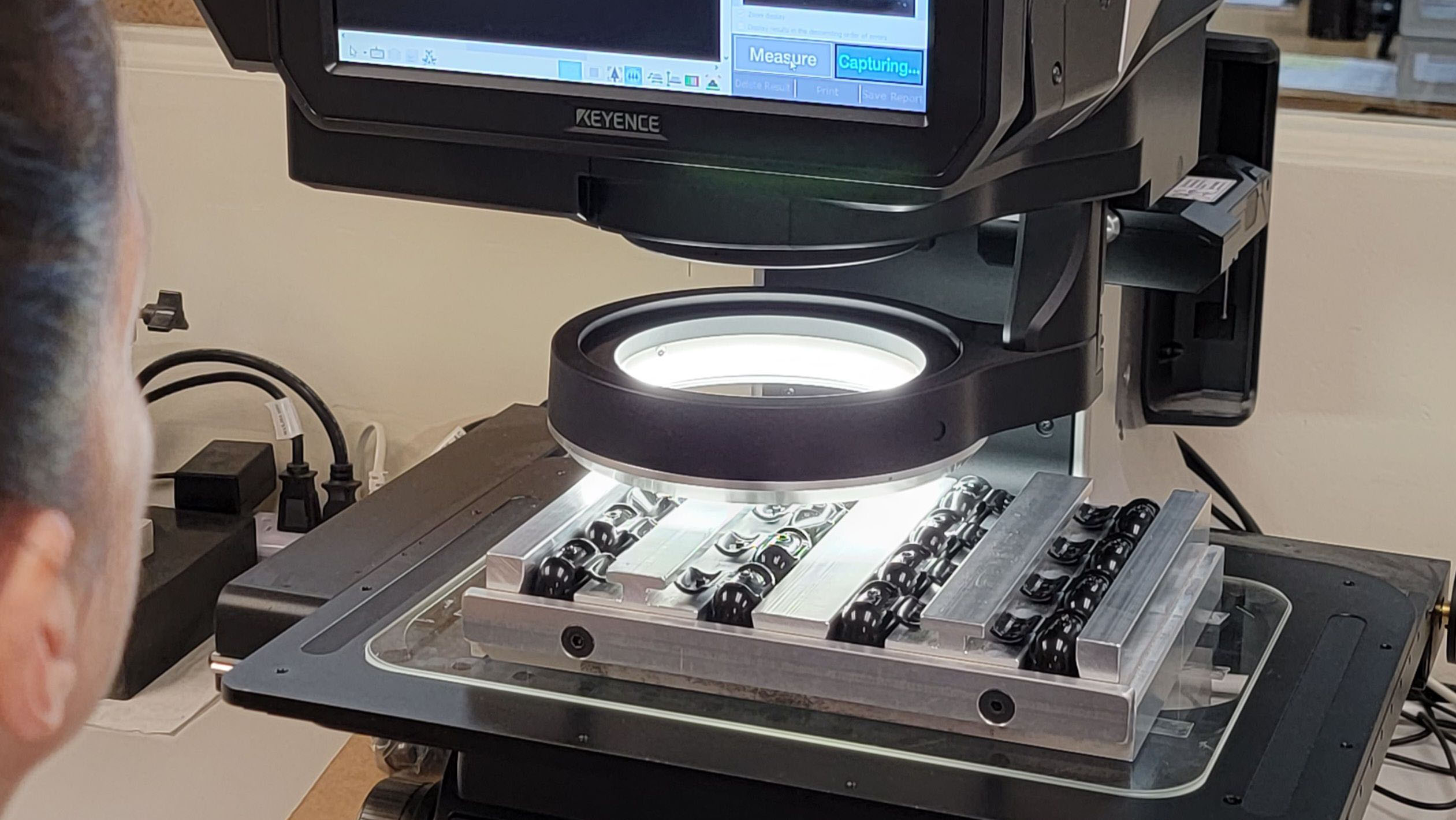

THOROUGH TESTING AND VALIDATION OF THE PROCESS

-

- Before your product goes into production, we conduct a complete qualification to ensure the entire process consistently produces the highest level of quality

- Protocol is developed based on your requirements and testing is implemented

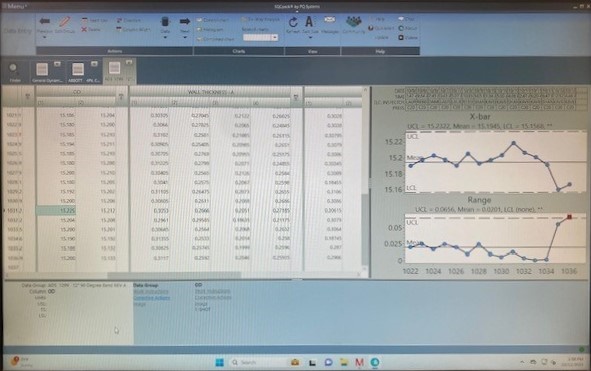

- Data is analyzed , verified and documented

PRODUCTION PLANNING

- Once the process has been validated, we will develop the appropriate documents (procedures, work instructions, ongoing testing requirements, training, data collection, etc.) to ensure all employees understand the expectations and have the necessary training and guidance to perform their job and produce superior products

PRODUCTION

- Our job does not end after the process is up and running; we continually work to improve and optimize every step of the process

- We collect and analyze production and quality data to identify opportunities for improvement and cost reduction